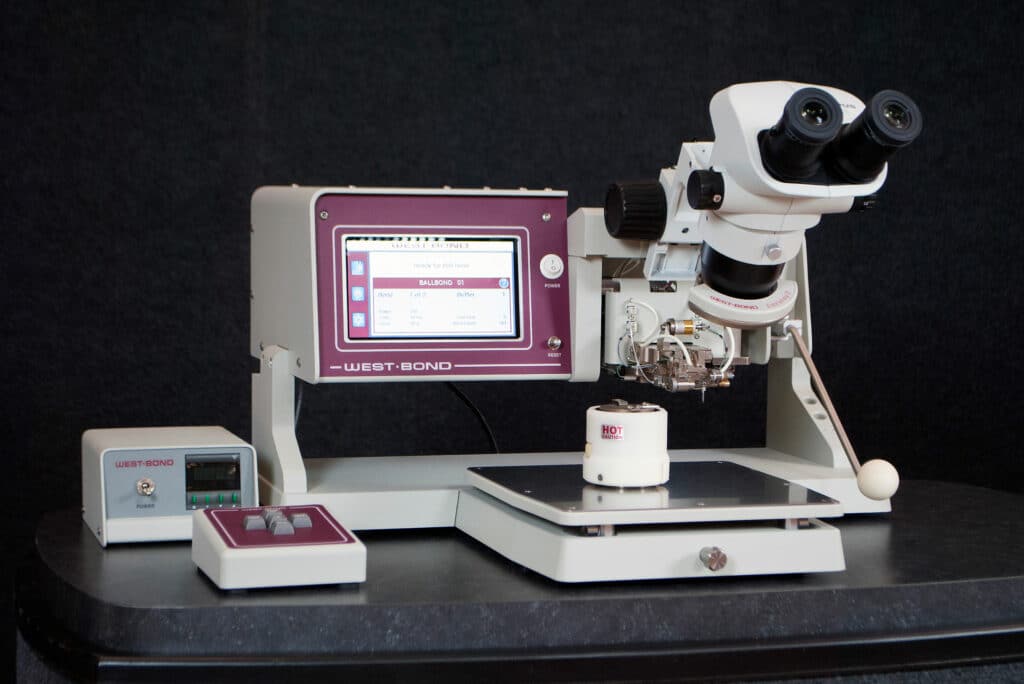

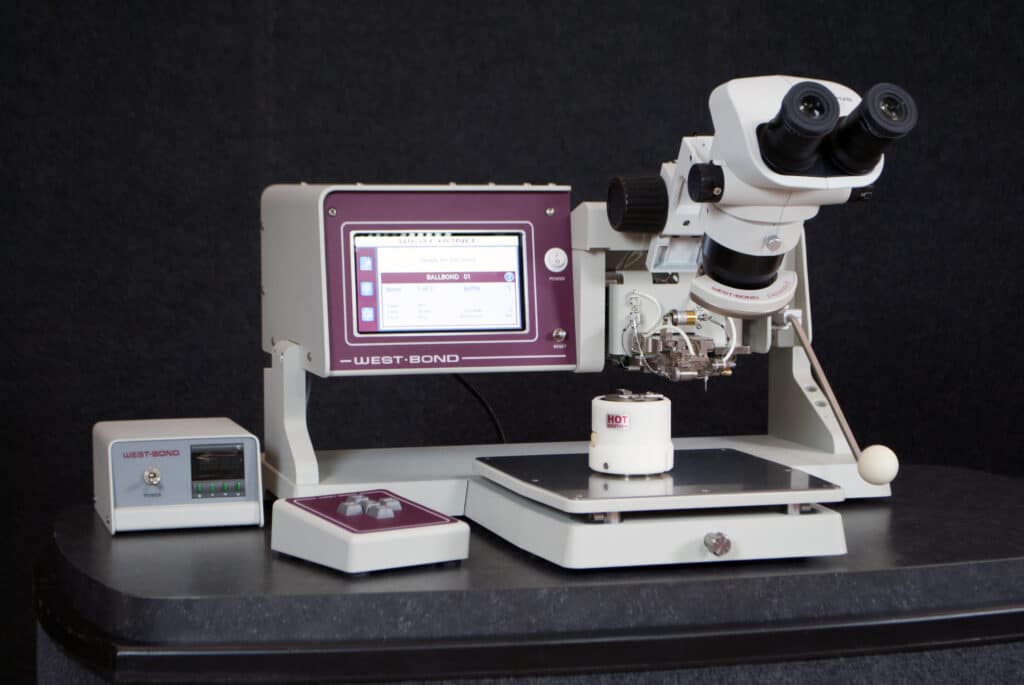

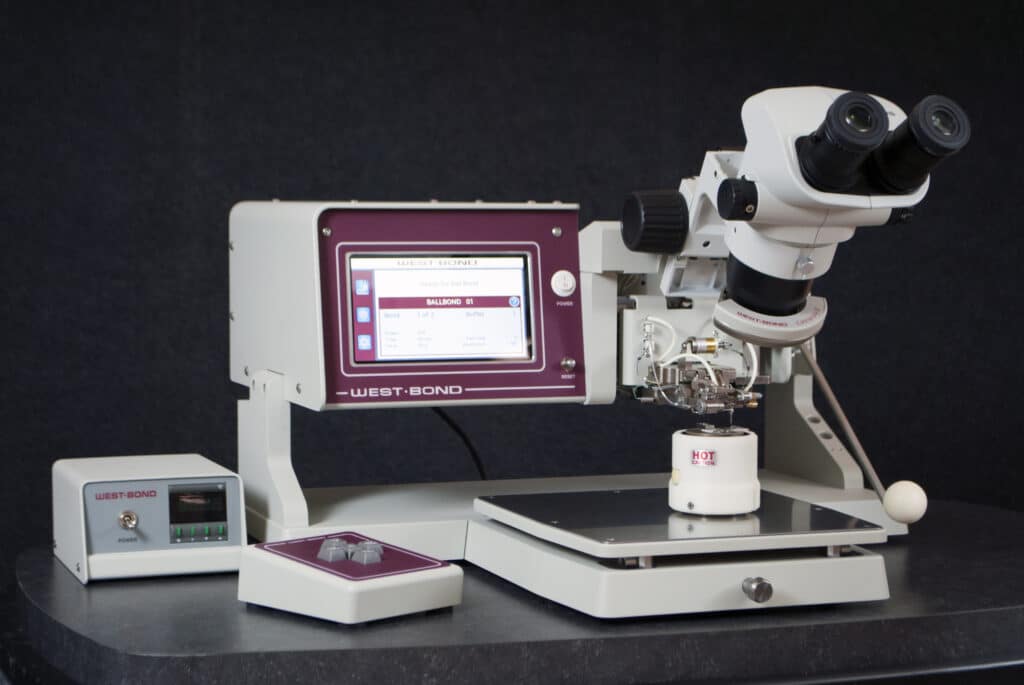

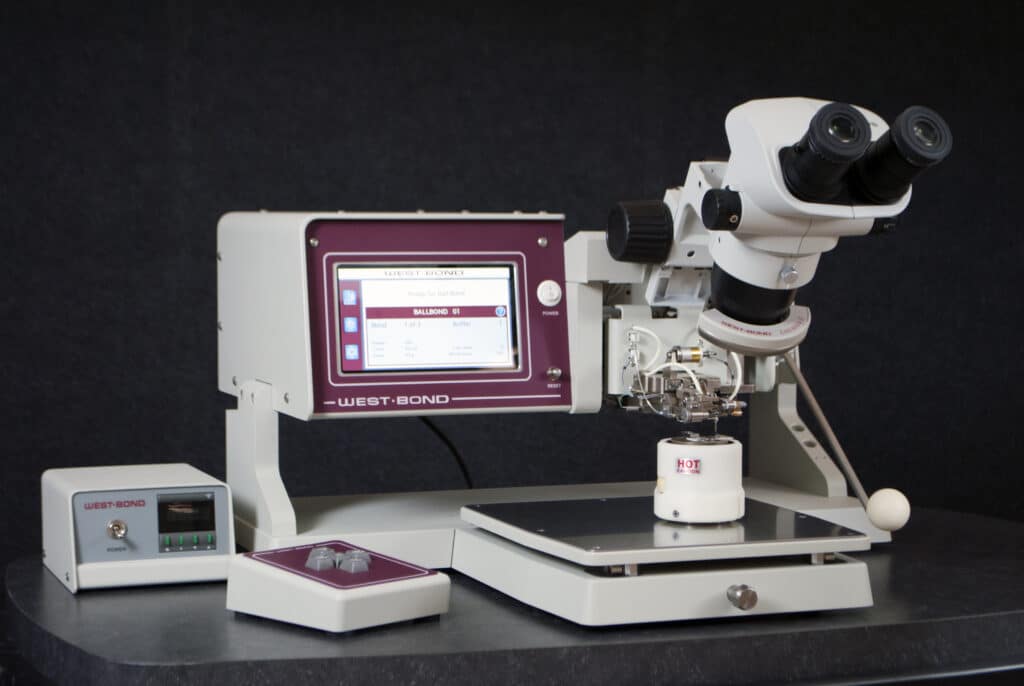

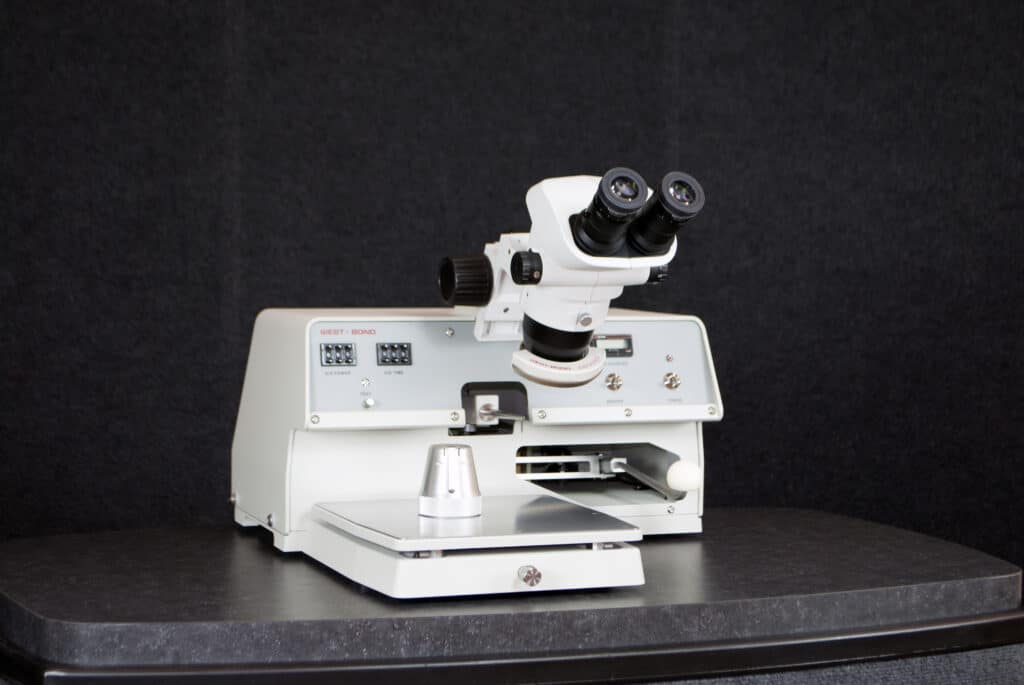

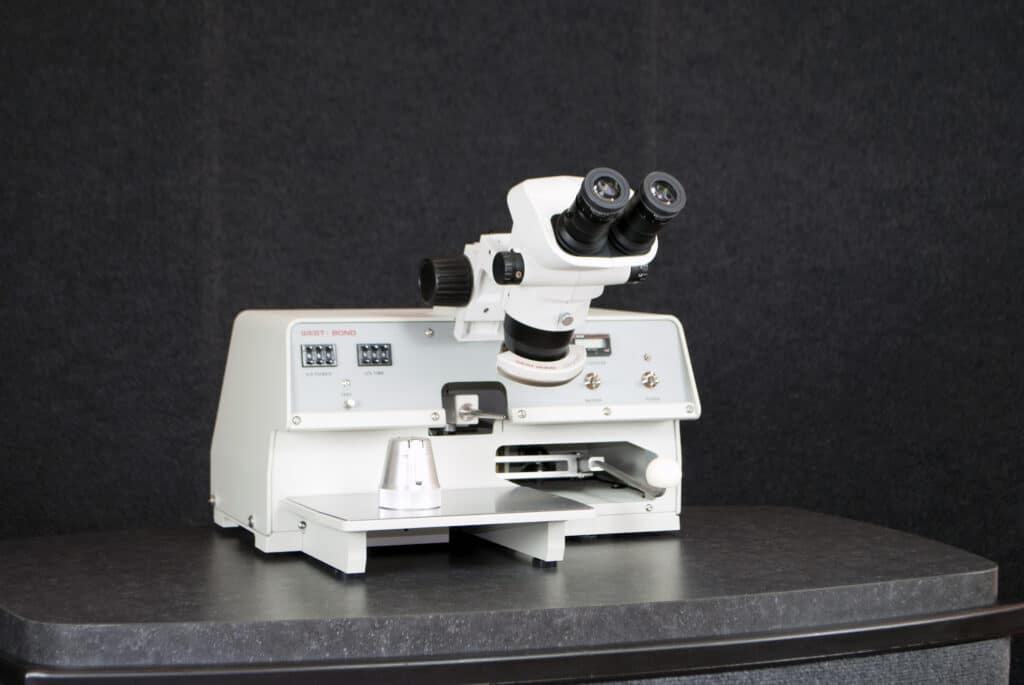

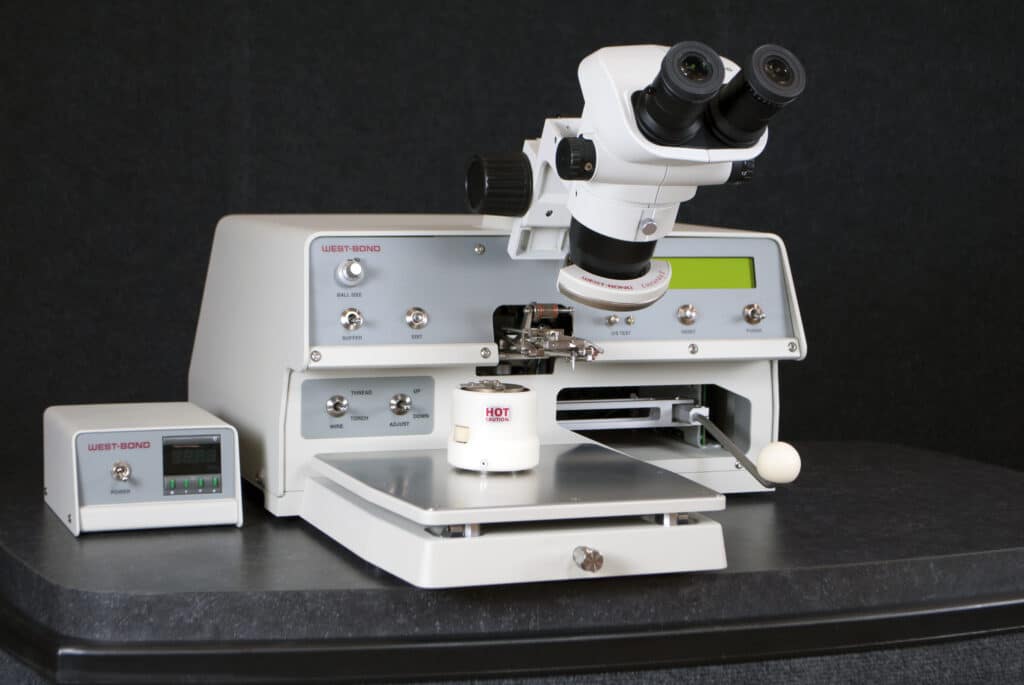

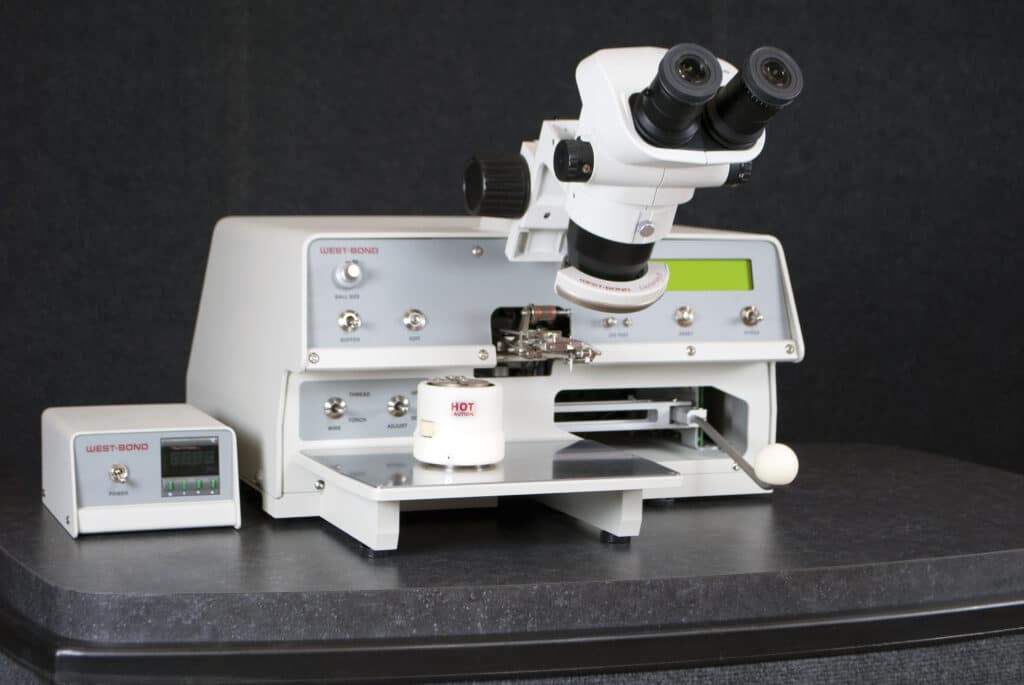

The machines of WEST•BOND’S Model 7440E Series are dedicated ultrasonic wire bonders for interconnecting insulated, gold plated, copper wire to thin film sliders or Flex-Circuits of Computer Disk Drives, or for other similar insulated wire connection applications.

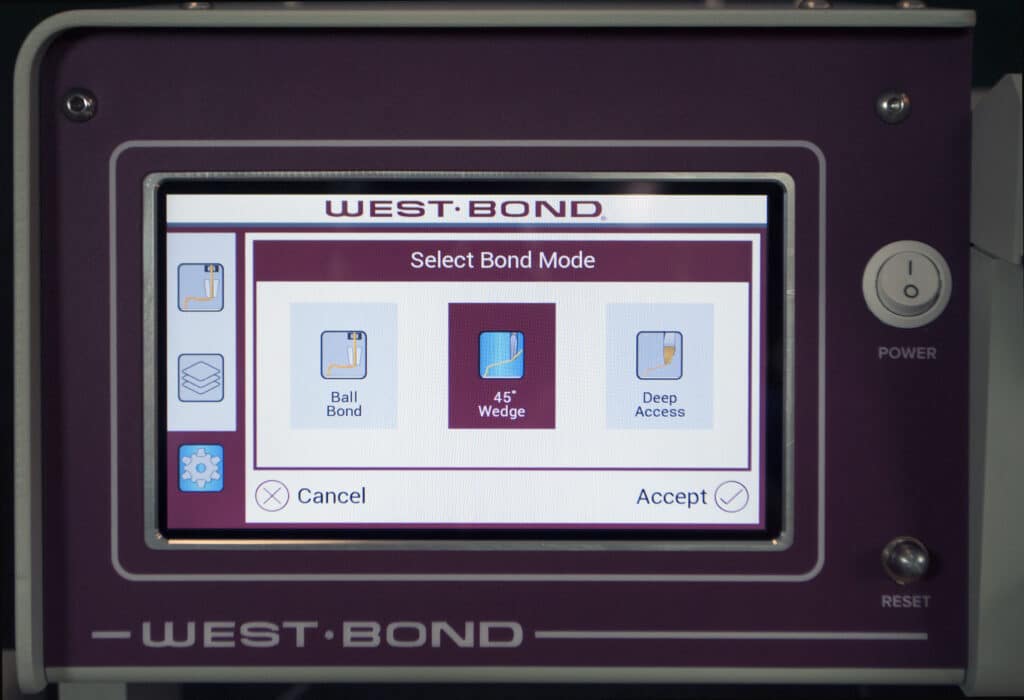

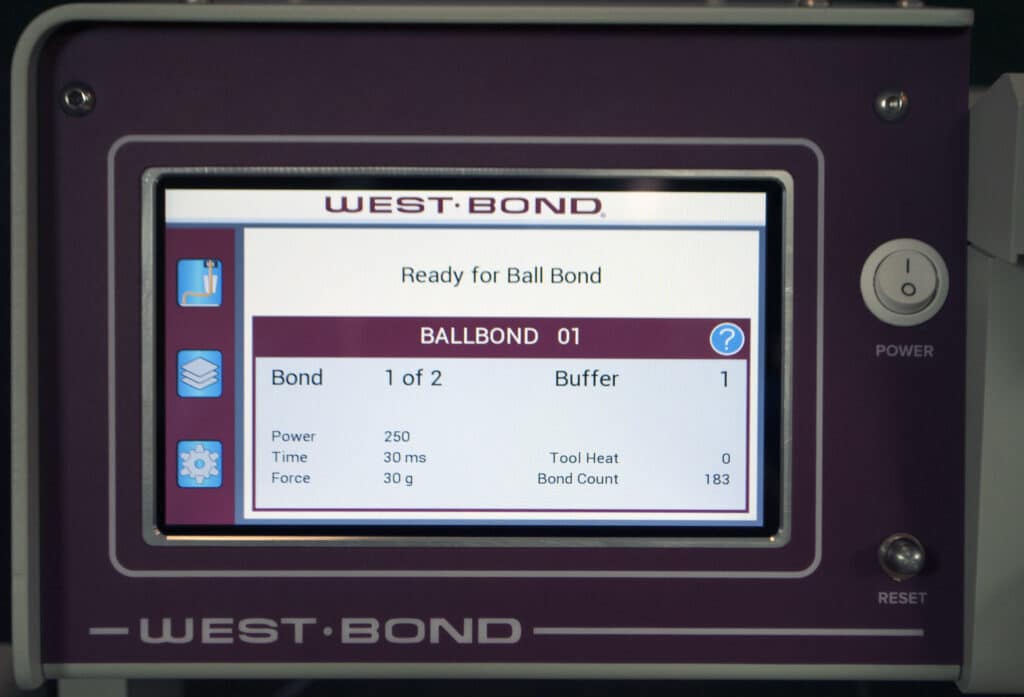

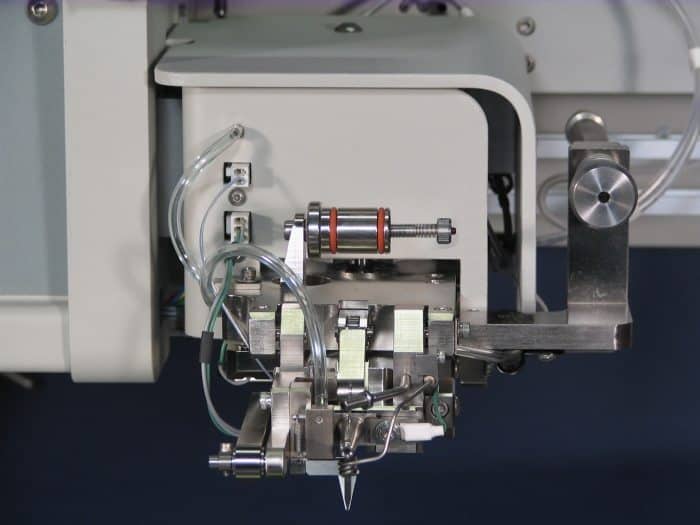

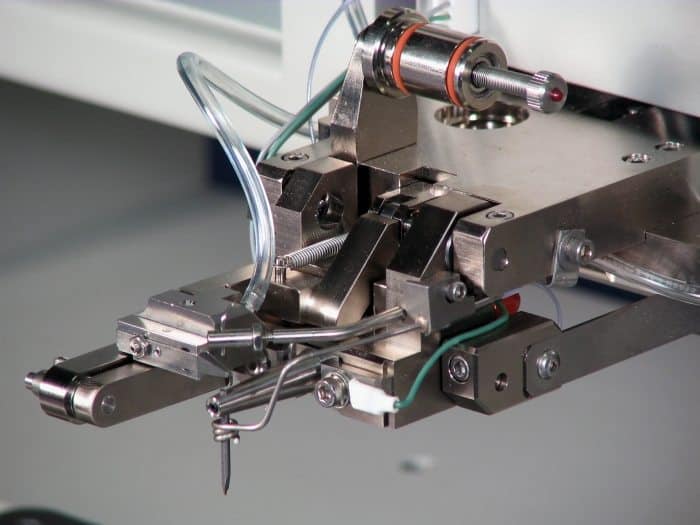

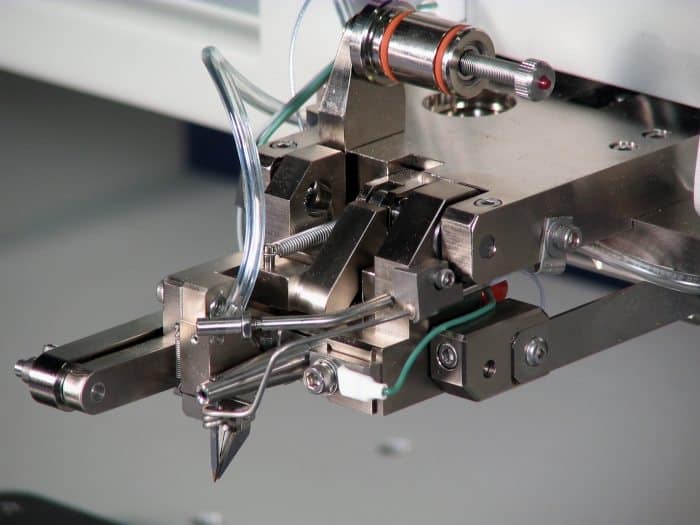

These machines bond insulated wires of 0.0007 to 0.002 inch diameter directly to thin film gold without the need to first strip off the insulation. This is accomplished by a specially designed wedge tool applied with programmed ultrasonic energy, force, and time, to soften and disperse insulation, then to bond the exposed wire to the work piece metallization. WEST•BOND’S unique single lever X-Y-Z micromanipulator makes it possible to use this process for bonding disk sliders by enabling the operator to engage a free standing end of a twisted wire pair in mid air and direct that end to touch down on the work piece at the bond target, all under microscope observation. Touchdown is sensed by the machine to initiate the bond program.

Embodied in this series is a new and unique WEST•BOND three-axis micromanipulator in which the entire mechanism is arrayed above the work plane, so that there is now no limit to the size of a work piece. Each of the X, Y, and Z axes is straight-line and purely orthogonal, and each can be braked pneumatically on signal. In this application, all axes are braked during the ultrasonic bond time to aid operator control.