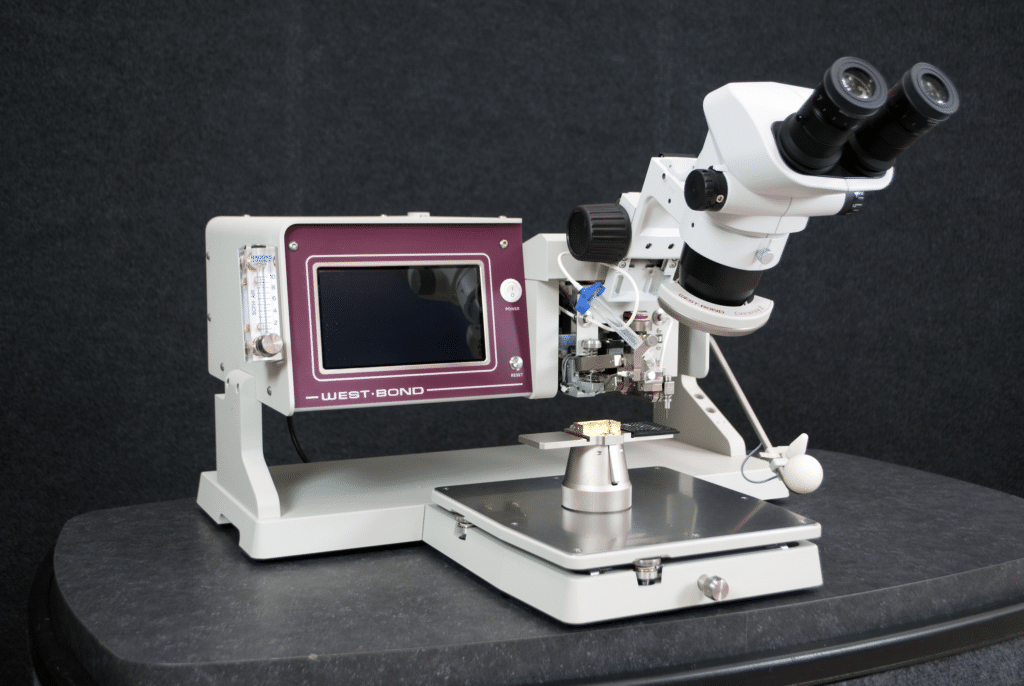

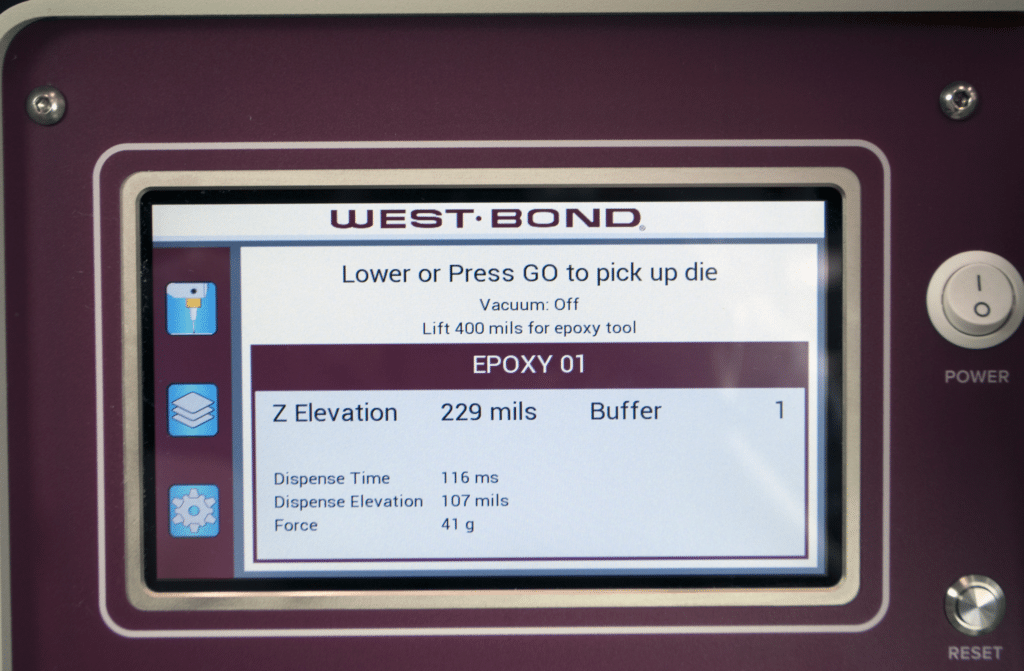

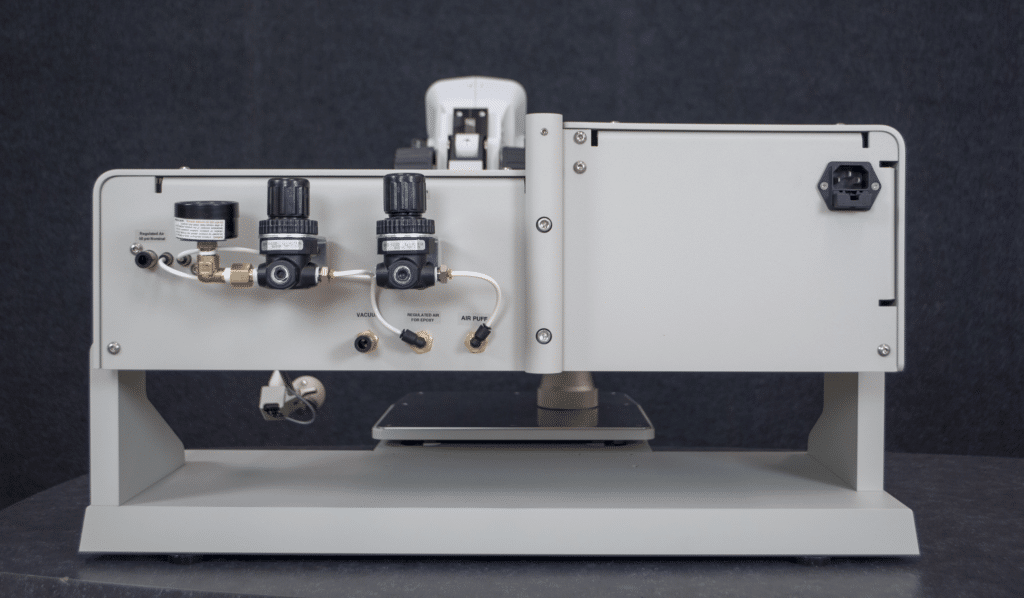

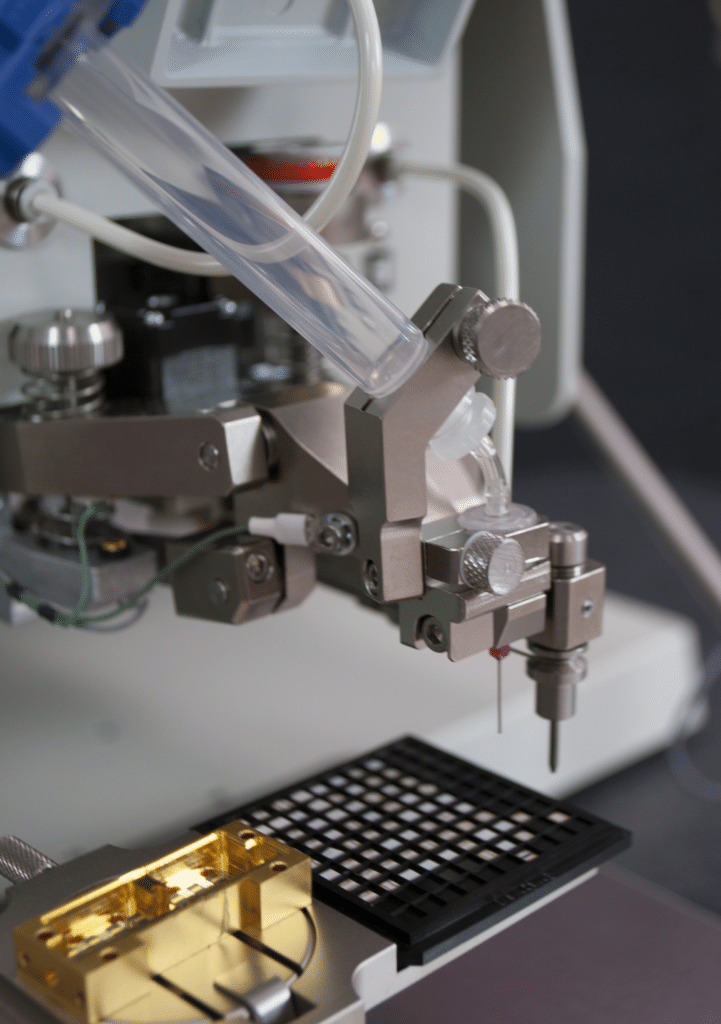

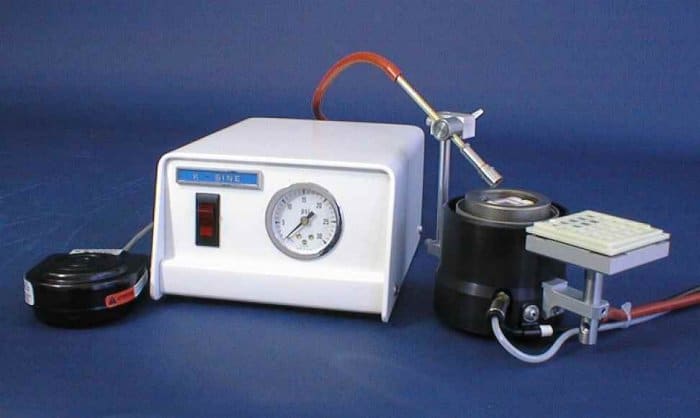

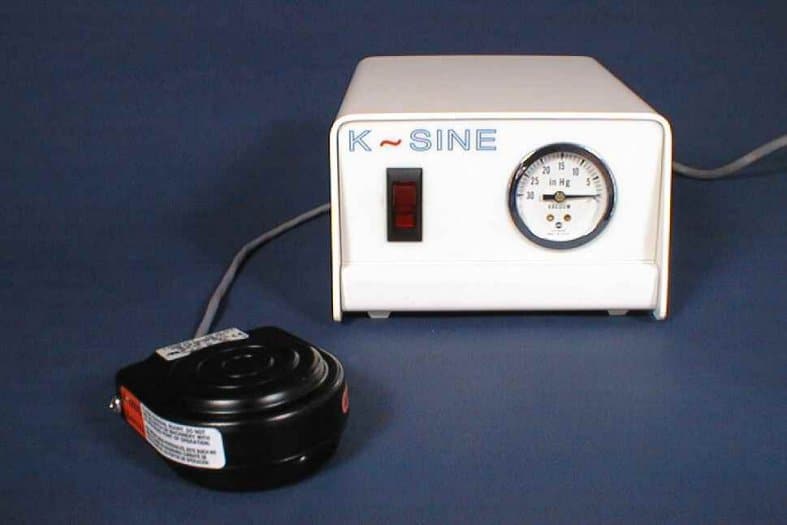

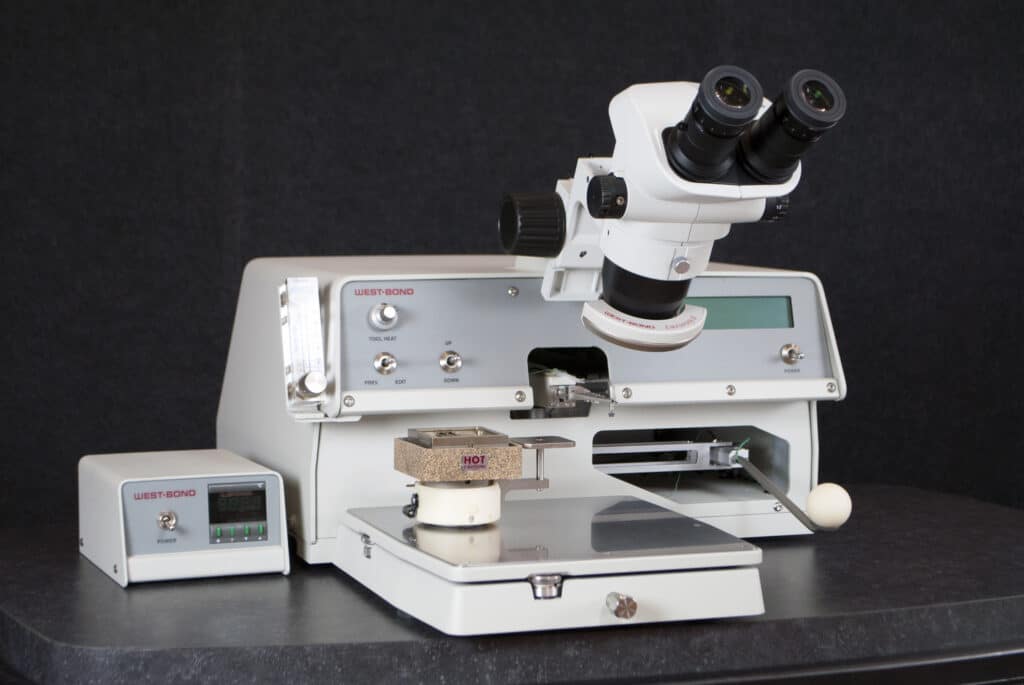

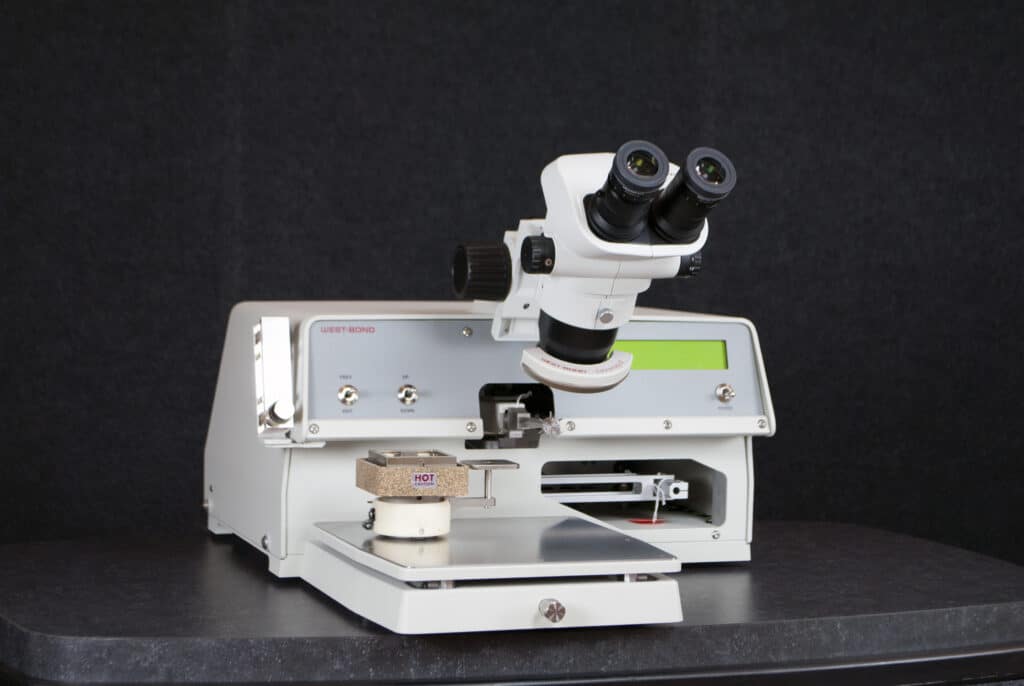

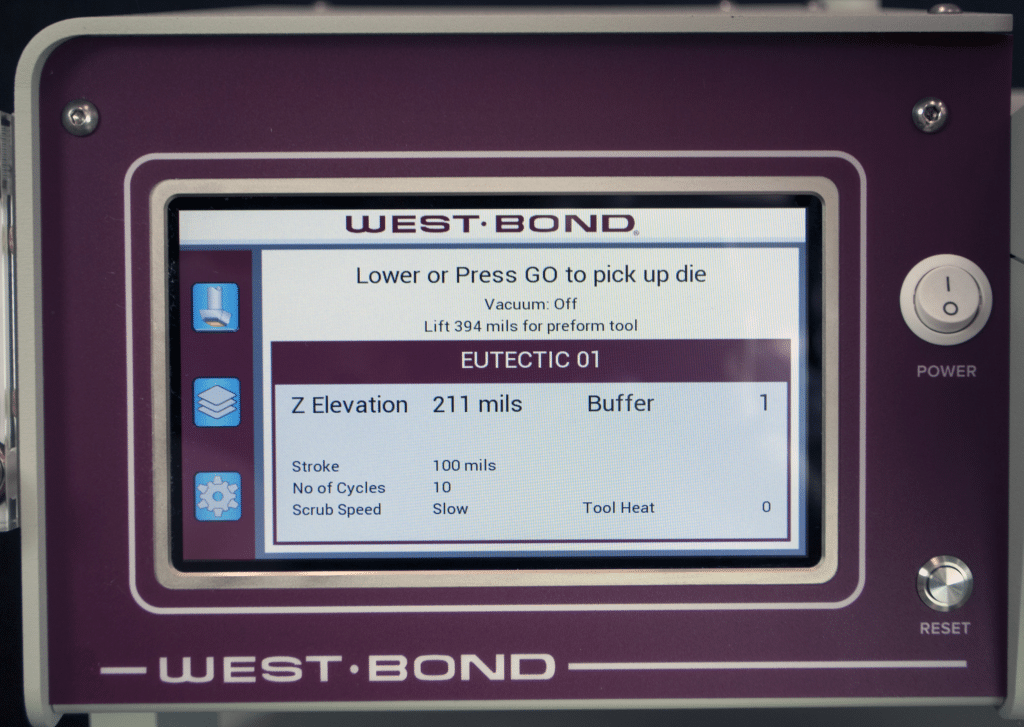

With the same UNLIMITED DEEP REACH access to remote bond targets on large packages as the original E Series machines. This system goes a bit further with a 7” capacitive touch screen and programmable force control utilizing the Cortex M7 microcontroller. This machine is a great addition to any microwave, semiconductor, RF or Hybrid application, and an ideal repair station for laboratory use.

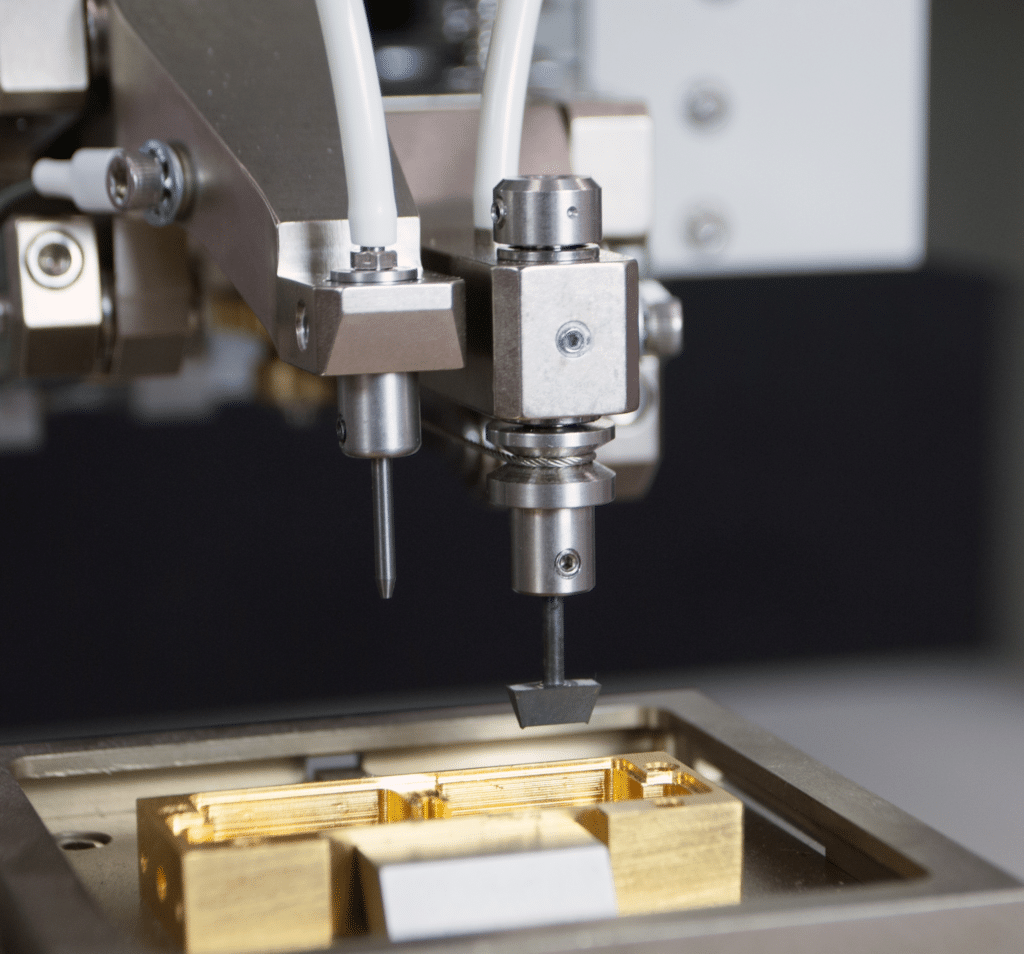

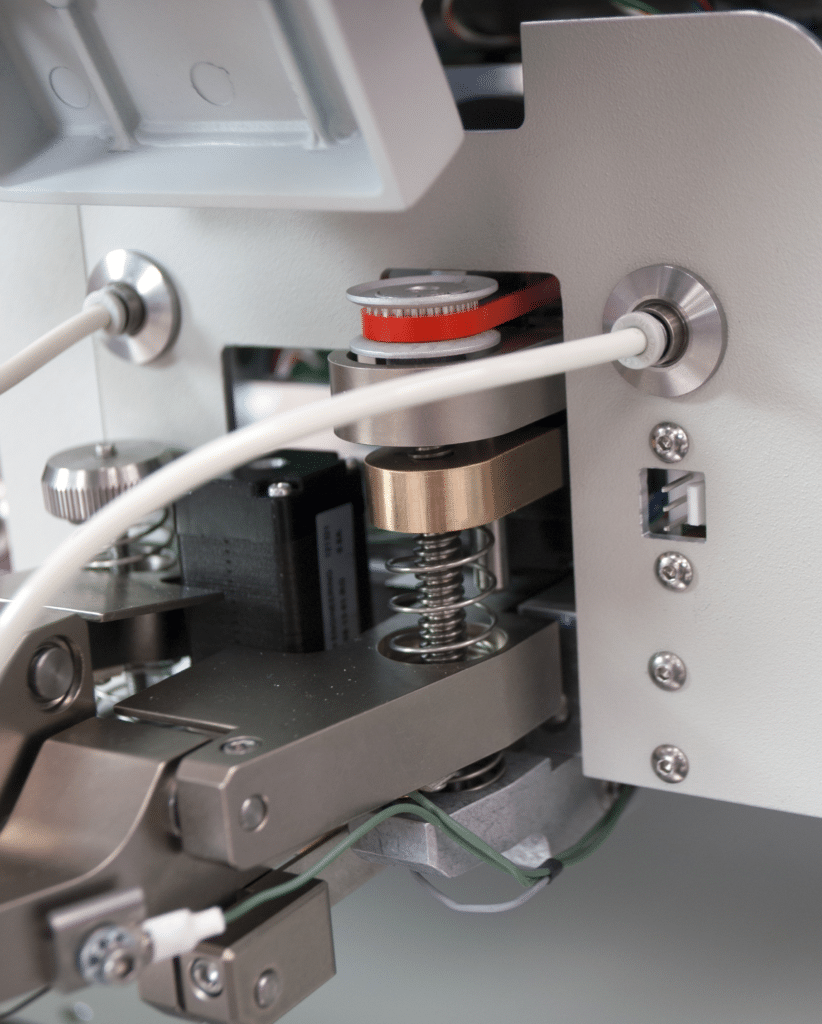

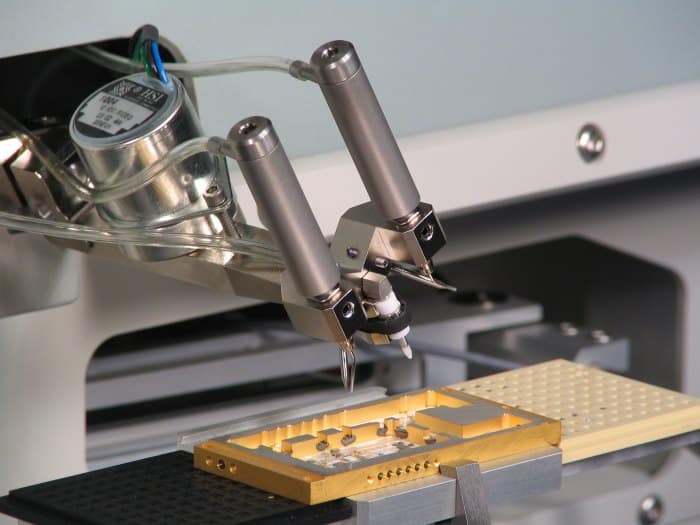

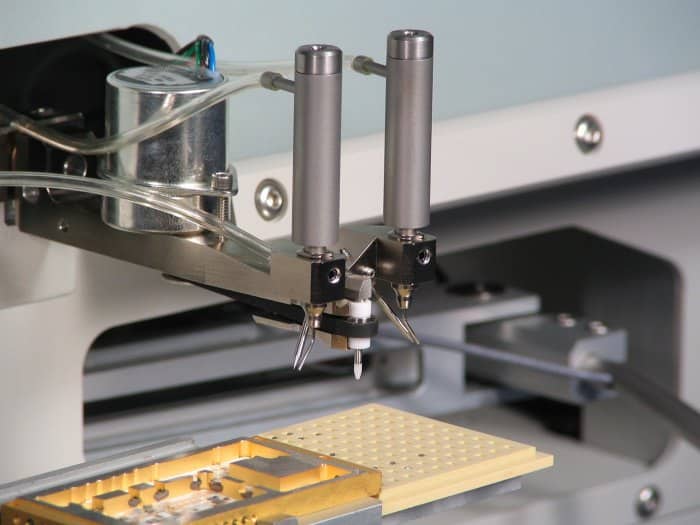

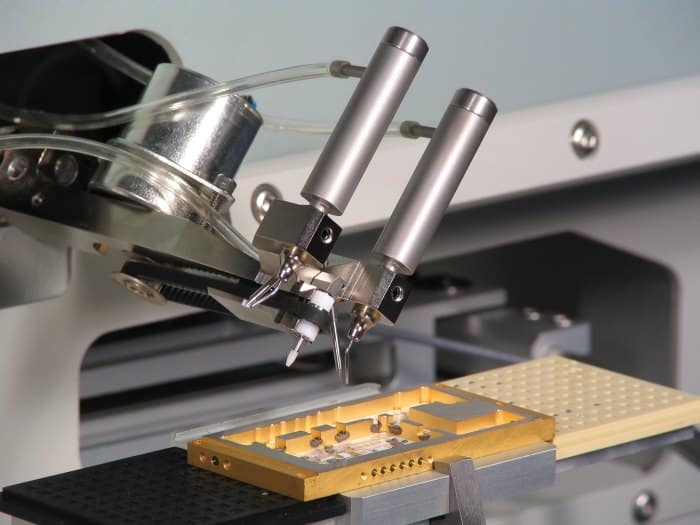

CONVERTIBLE model 73KF includes the same interchangeable tool head assemblies for bonding by either epoxy or eutectic methods. Pick-up tool rotation and radiant heater are standard. All programmed bond variables for each tool head assembly are retained in memory and are retrieved upon conversion.